An up to date summary of the development of FastFloor C was provided at the 13th International Conference on Advances in Steel-Concrete Composite Structures (ASCCS 2024), in Hong Kong, China, on December 13, 2024. An audience of international researchers and local Hong Kong structural engineers were provided a keynote lecture delivered by Ben Schafer addressing the paper “FastFloor – Development of a Novel Modular Steel Floor System for Commercial Construction in the United States.” by Schafer, B.W., Avci, O., Easterling, W.S., Eatherton, M.R., and Hajjar, J.F.. A preprint of the conference paper is available at engrXiv: https://doi.org/10.31224/4183. The abstract and linked references are provided below.

Abstract

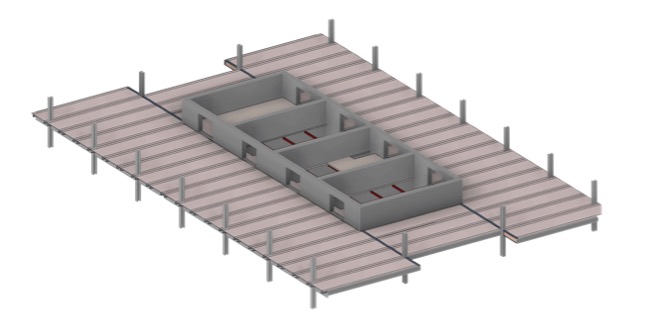

This paper describes a research program for a new prefabricated, modular, steel floor framing system being developed in the United States. Conventional steel building construction in the United States utilizes steel deck, shear studs, and poured concrete for most floor systems. Conventional floors have proven structural and non-structural performance; however, they are time consuming, labor intensive, and have high embodied carbon. In partnership with the Pankow Foundation and the American Institute of Steel Construction a modular, shop-fabricated, all-steel floor system, known as ‘FastFloor’ has been envisioned. Combined with a raised access floor for accommodating mechanical, electrical, and plumbing the system can be constructed at speed and with high potential performance. Research is underway to specifically address the vibration, acoustic, and structural performance of the floor system. The research program and preliminary results for this new floor system are summarized.

Keywords

- Modular floor system;

- All-steel floor system;

- Floor vibrations;

- Local buckling;

- Diaphragm bracing;

- Raised access floor

References

[1] AISC (2024) Need for Speed Initiative.

[2] Huber, D. and Varma, A. (2021) “Core Value”. Modern Steel Construction, March 2021, p. 30-37.

[3] Eatherton, M.E. et al. (2020). “Steel Diaphragm Innovation Initiative: Year 5 Final Report”. https://steeli.org/?p=293

[4] Mercado, M.A. (2023) “Vibration Serviceability Assessment of a Steel Modular Floor System.” M.S. Thesis, Virginia Tech.

[5] Boadi-Danquah, E., et al. (2017). Lightweight modular steel floor system for rapidly constructible and reconfigurable buildings. IJCMEM, 5(4), 562–573. DOI

[6] Avci, O. et al. (2023). “Vibration Serviceability Evaluation of a Modular Steel Plate Floor Assembly.” SEM IMAC. pp. 269-275.

[7] Avci, O. et al. (2024). “Vibration Testing of an All-Steel Modular Floor Assembly.” SEM IMAC. pp. 17-23

[8] Rifai, S. et al. (2025) “Effect of Bottom Flange Angle Blocking on the Dynamic Response of Two All-Steel Laboratory Floors.” SEM IMAC 2025.

[9] Rifai, S. et al. (2025). “Modal Testing and Finite Element Model Updating of a FastFloor Specimen: A Modular All-Steel Floor System.” SEM IMAC 2025.

[10] Rifai, S. et al. (2025). “Vibration Serviceability Evaluation of an All-Steel Floor System using the High-Frequency Floor Procedure.” SEM IMAC 2025.

[11] Kumar, R.C.M. et al. (2023). “Efficient stability and vibration analysis of an all-steel modular floor assembly.” SSRC Conf. Proc., presentation.

[12] Kumar, R.C.M. et al. (2024). “Effect of intermittent edge support on in-plane plate compressive strength.” SSRC Conf. Proc.

[13] Caswell, H.L. et al. (2022). “FastFloor Residential Testing Report”. CFSRC-22-03.